Project Description

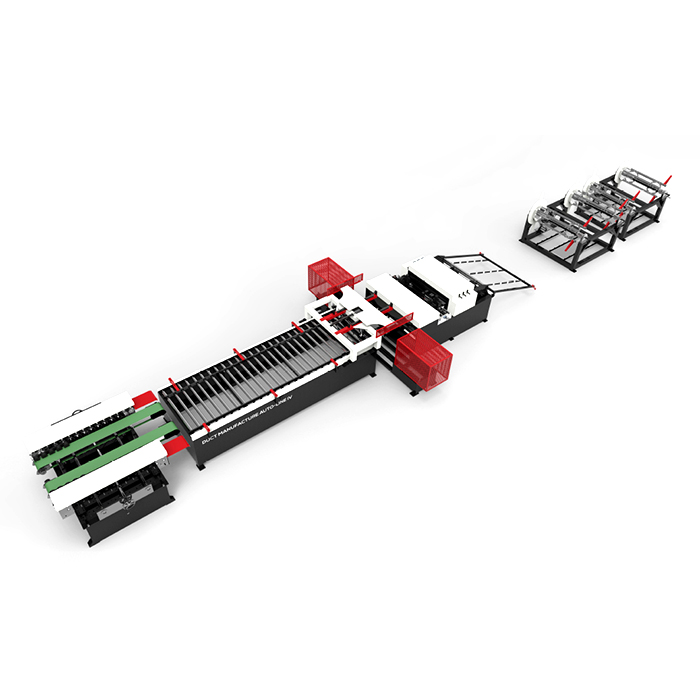

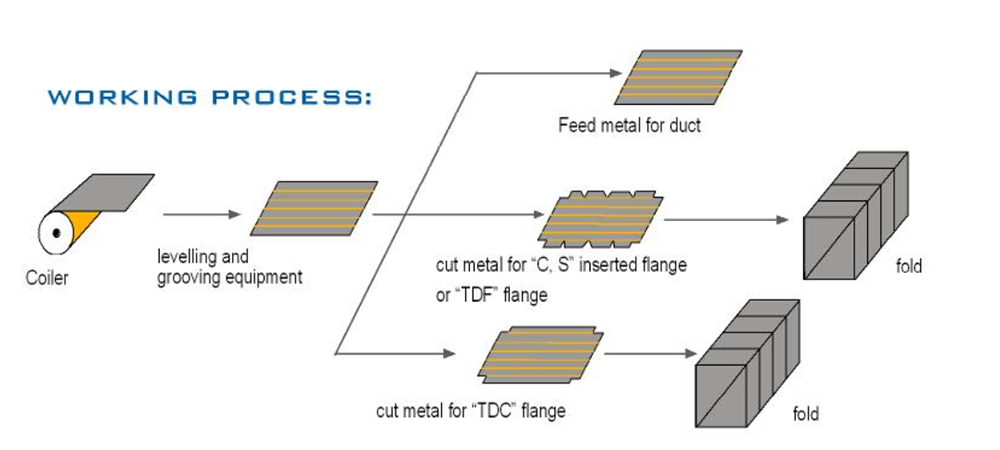

HVAC Rectangular Duct line Square duct Auto Production Line II for Square Duct Forming Making

Main Features:

The latest design can resolve the problems like getting struck, too many repairs form roll-shearing displacements lock machine.

The three-line bending function can crimp narrow edges and stably process 0.5-1.2mm galvanized sheet to avoid wasting.

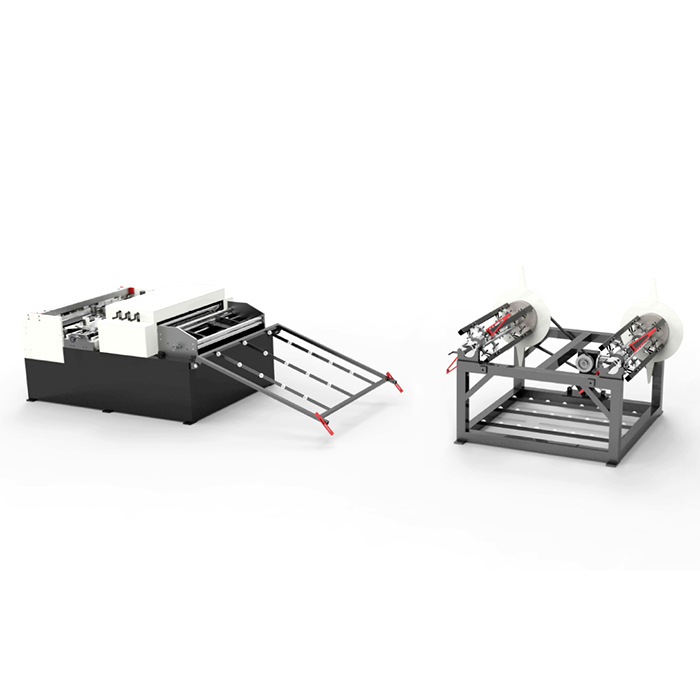

Mechanical arm clutching, locating and transferring platform

Displacement lock machine

Line 3 host+ Single rack

Main Import Configuration:

MITSUBISHI HMI Display And PLC

MITSUBISHI Frequency Converter

Japan NEMICON Inverter

Taiwan Hydromax Pump

Taiwan High Temperature Resistant Tubing

Basic Configuration:

One electric coil cradles, 2 material trays (5-7t each roll)

One rack

One host (line 2 host)

One mechanical arm clutching, locating and transferring platform

One displacement type locking machine

One set of computer controlling system

| Technical Data | ||

| Model | DML-II-1250 | DML-II-1550 |

| Thickness (mm) | 0.5-1.2 | 0.5-1.2 |

| Max width (standard) (mm) | 1250 | 1550 |

| Max working speed( m/min) | 18 | 18 |

| Coiler Max-weight (KG) | 8000 | 8000 |

| Power (KW) | 8 | 8 |

| Weight | 3000 | 3500 |

| Dimension | 1900*1800*1400 | 1900*2100*1400 |