Project Description

Q35Y series metal sheet ironworker with punching ,bending ,cutting function

Main Features:

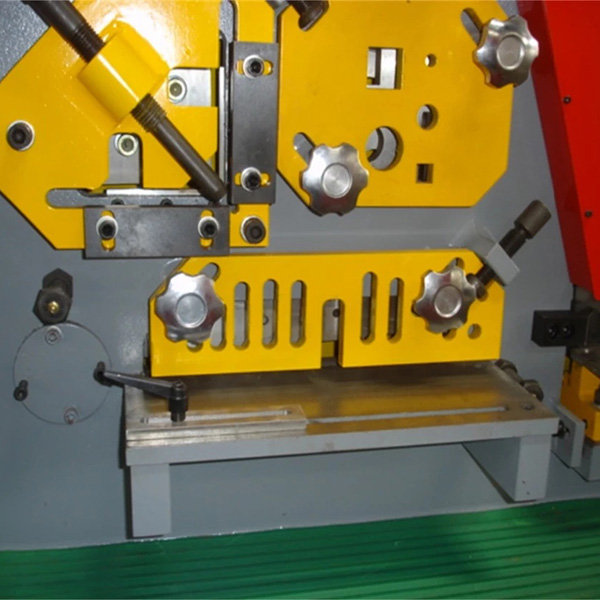

Ironworker machine, also called punch shears.It is one a kind of machine which combined the function of metal cutting, hole punching, plate cutting, notching, and bending.

It has features of easy operation, low energy consumption, low maintenance cost, etc, Mainly applied in metallurgy, bridge, communication, electric power, military industry.

The structure includes:

Double cylinders hydraulic punch & shear machine

Five independent stations for punch, shear, notcher, section cut

Large punch table with multi-purpose bolster

Removable table block for overhang channel / joist flange punching applications

Universal die bolster, easy change punch holder fitted, punch adapters supplied

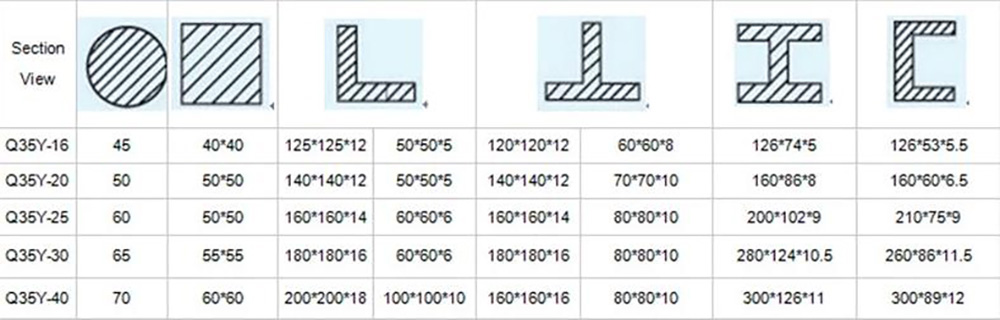

Angle, round & square solid monoblock crop station

Rear notching station, Low power inching and adjustable stroke at punch station

Centralised pressure lubrication system

Electric panel with overload protaction elements and ingetrated controls

Safety movable foot pedal

| Technical Data | |||||

| Max.ctting thickness(mm) | 12 | 16 | 20 | 25 | 30 |

| Plate strength (N/mm2) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

| Cutting angle | 7° | 7° | 8° | 8° | 8° |

| Shearing size of one stroke(mm) | 12×220 | 16×250 | 20×330 | 25×330 | 30×355 |

| 6×360 | 8×400 | 10×480 | 16×600 | 6×360 | |

| Ram sroke (mm) | 80 | 80 | 80 | 80 | 80 |

| Number of srokes(cpm) | 8 | 8 | 8 | 6 | 15 |

| throat depth (mm) | 250 | 300 | 355 | 400 | 600 |

| Max.punching thickness | 12 | 16 | 20 | 25 | 26 |

| Punching diametre (mm) | 20 | 25 | 30 | 35 | 38 |

| Max. Punching diametre | 25 | 32 | 40 | 50 | 50 |

| punching thicknee (mm) | 8 | 10 | 12 | 15 | 20 |

| Power of main motor(KW) | 3 | 4 | 5.5 | 7.5 | 11 |

| Overall dimensions L×W×H(MM) | 1480×760×1620 | 1640×780×1770 | 1860×800×1900 | 2355×960×2090 | 2680×1040×2300 |

| Weight of machine (Kg) | 1230 | 1550 | 1920 | 4670 | 6450 |